Industries

Leading know-how

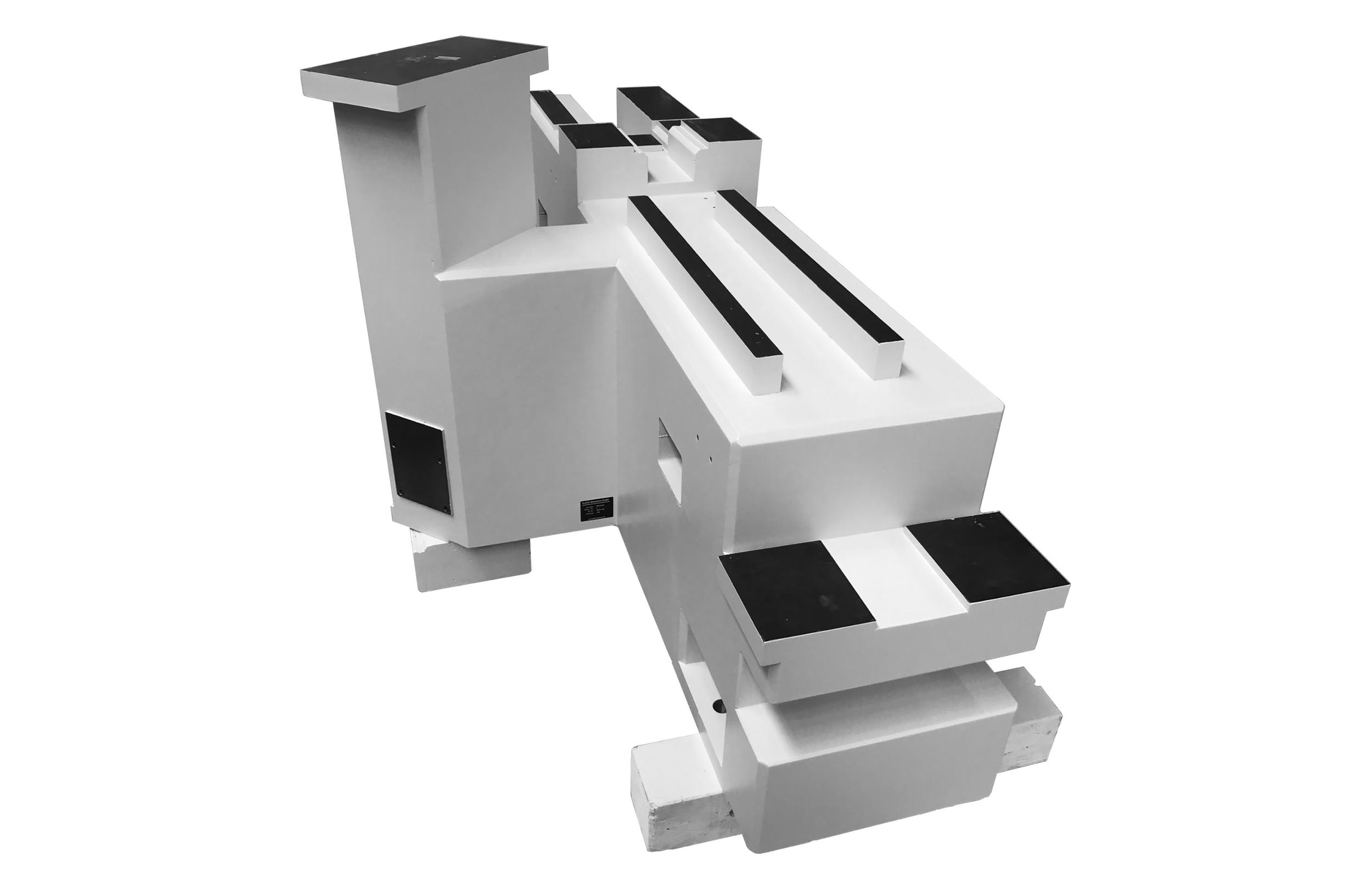

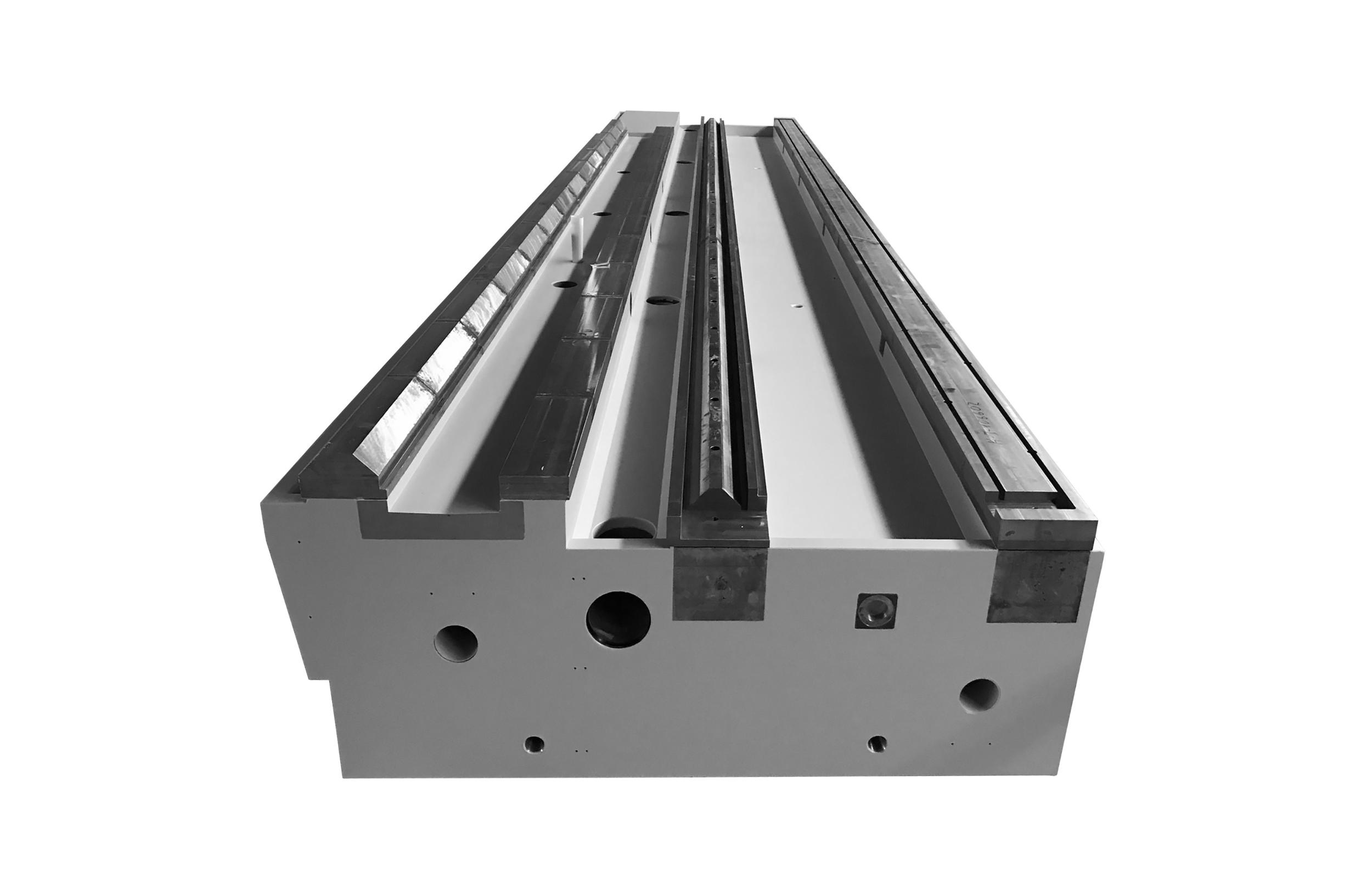

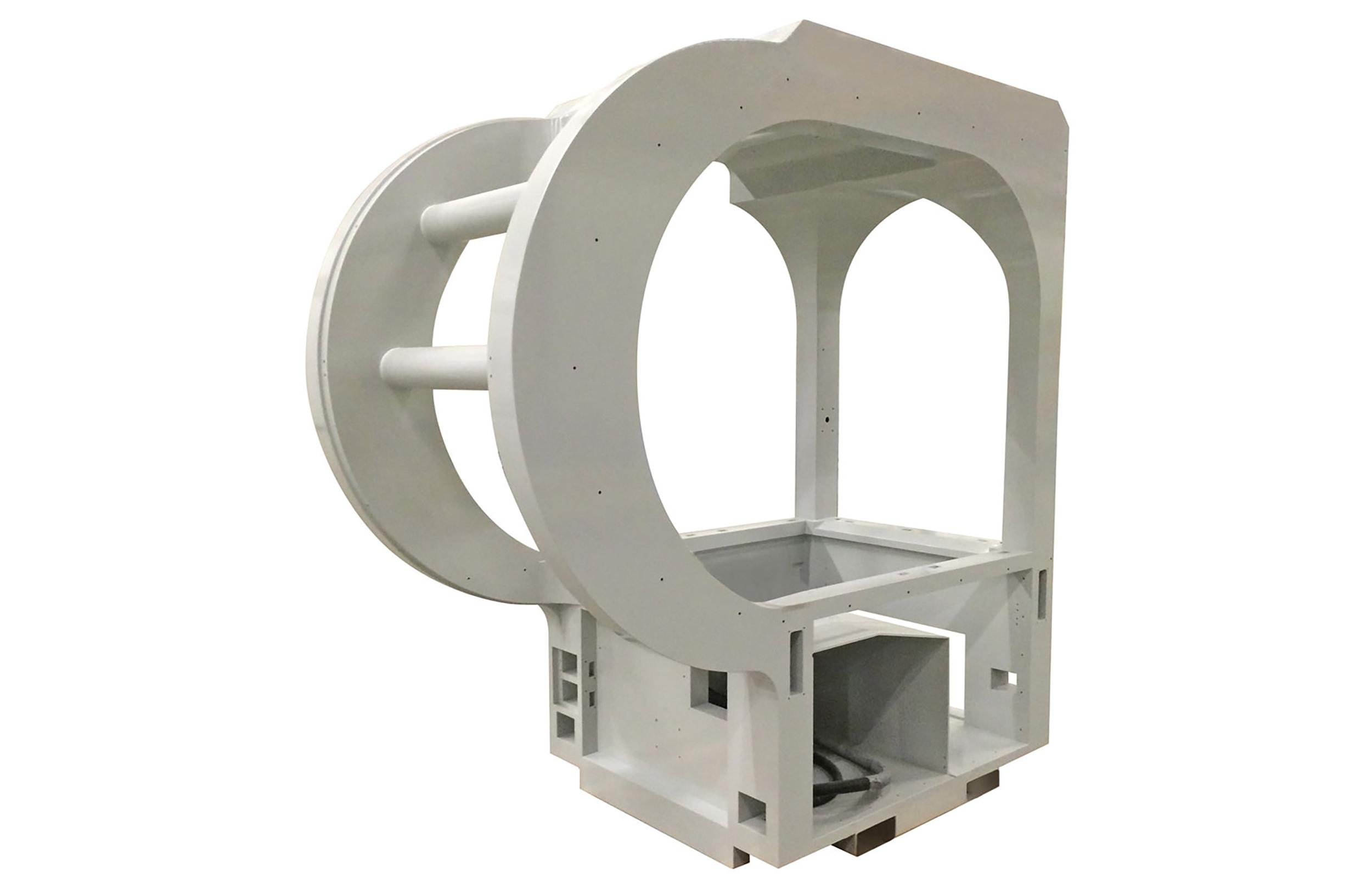

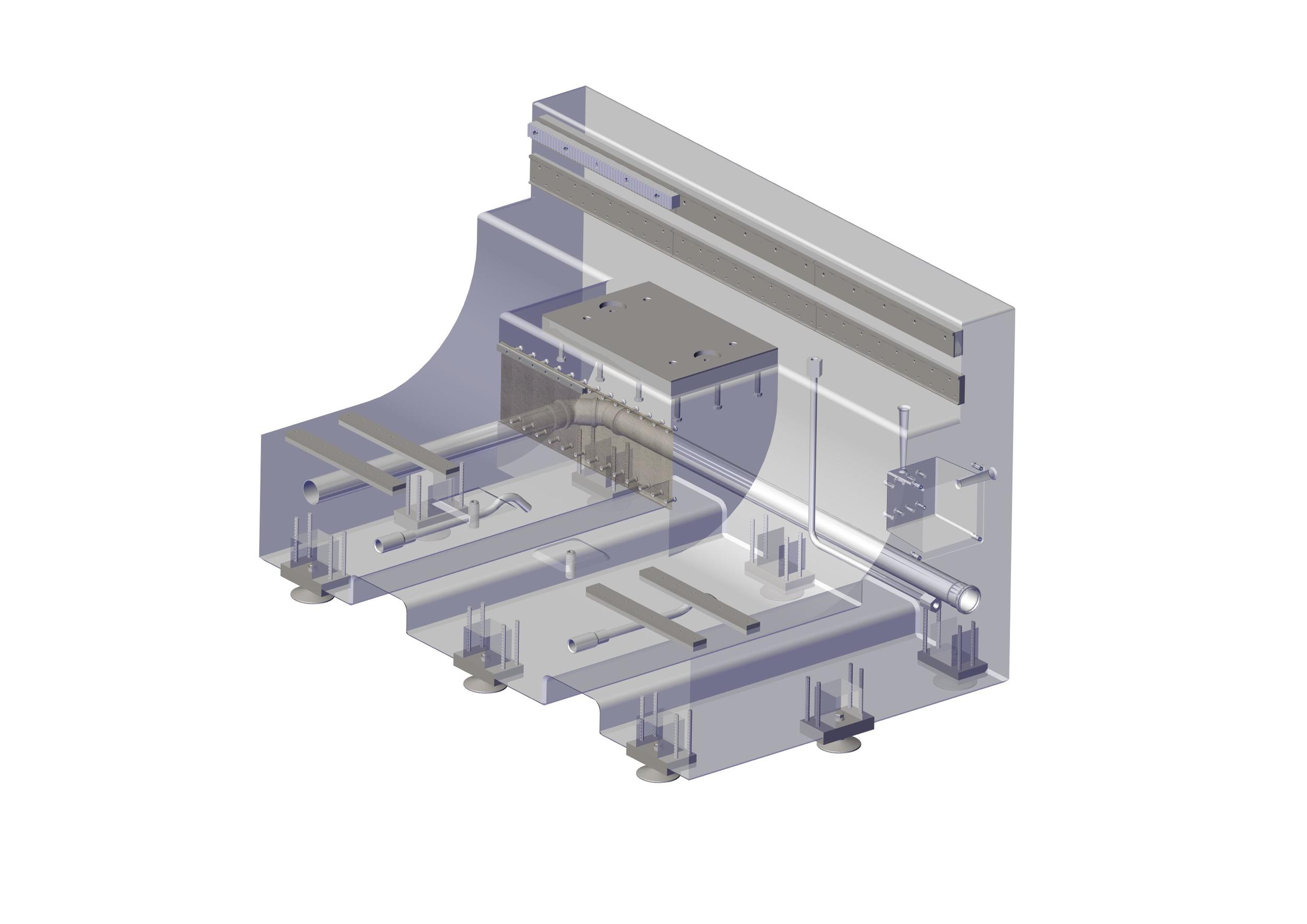

tailored solutions made of uhpc

The countless different applications of the innovative high-tech material UHPC are not yet foreseeable. As a pioneer, Sudholt-Wasemann has been developing and manufacturing industry-proven solutions for various industries in partnership with clients since 2009.

In our core business, machine engineering and industry, we are already the market leader in the application of ultra-high performance concrete and are always working hard to further maximize existing client benefits. In industries such as construction and infrastructure, mobility & energy, we enable the use of certain UHPC applications through initial research and pilot projects on future topics.

With our leading interdisciplinary know-how, we develop together with you tailor-made and trend-setting solutions for your industry.

In our core business, machine engineering and industry, we are already the market leader in the application of ultra-high performance concrete and are always working hard to further maximize existing client benefits. In industries such as construction and infrastructure, mobility & energy, we enable the use of certain UHPC applications through initial research and pilot projects on future topics.

With our leading interdisciplinary know-how, we develop together with you tailor-made and trend-setting solutions for your industry.