Ihr Browser unterstützt leider das HTML5 Video Element nicht.

future cast in concrete

Lösungen aus Ultrahochleistungsbeton (UHPC)

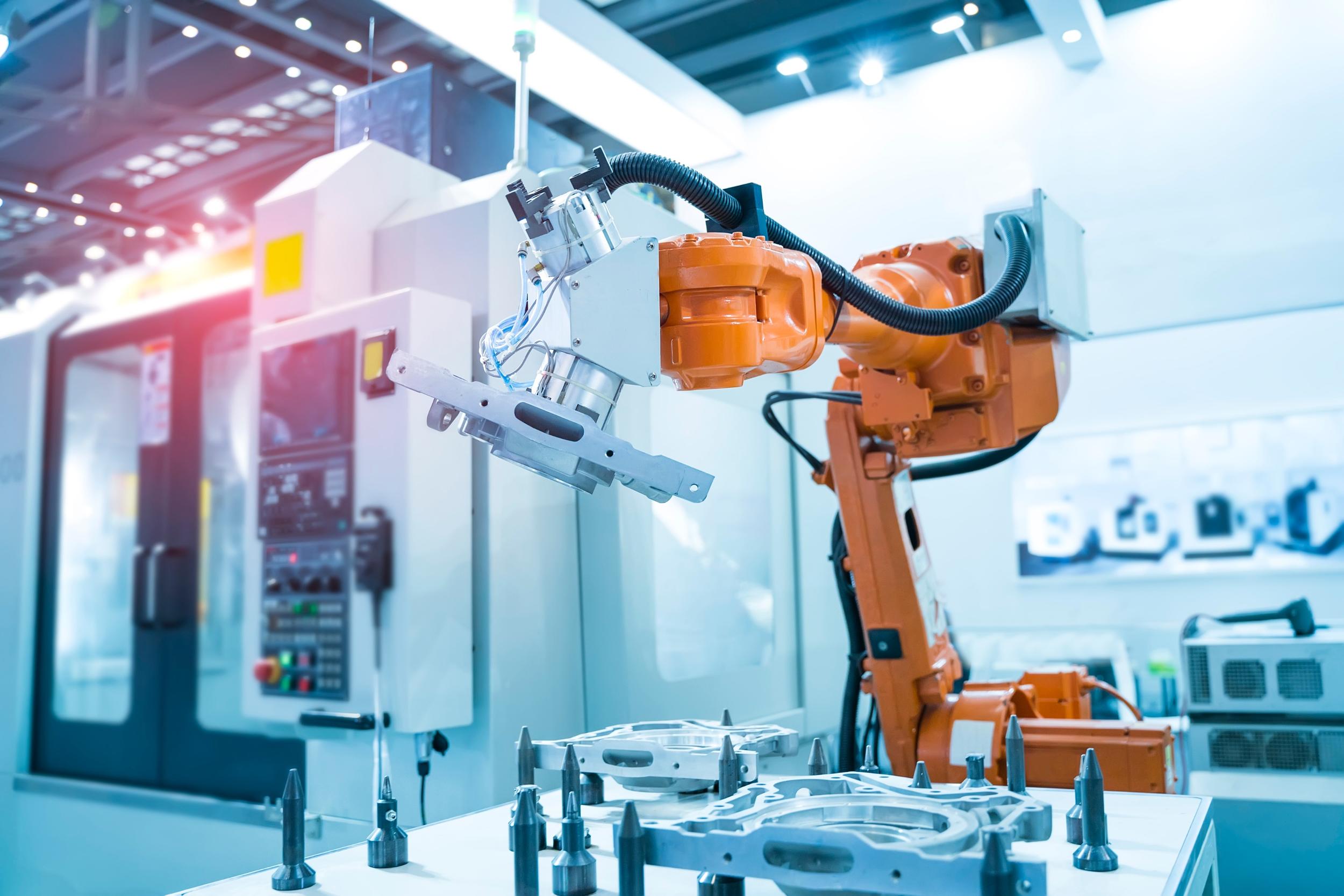

Als Vorreiter entwickelt und fertigt Sudholt-Wasemann hochtechnologische Maschinenbauteile und Elemente aus dem zukunftsweisenden Werkstoff Ultra High Performance Concrete (UHPC). Mit unserem interdisziplinären Know-how bieten wir Ihnen maßgeschneiderte, leistungsstarke und industrieerprobte Lösungen für ein breites Spektrum an Anwendungen im maschinenbau, in der industrie und im Bausektor.